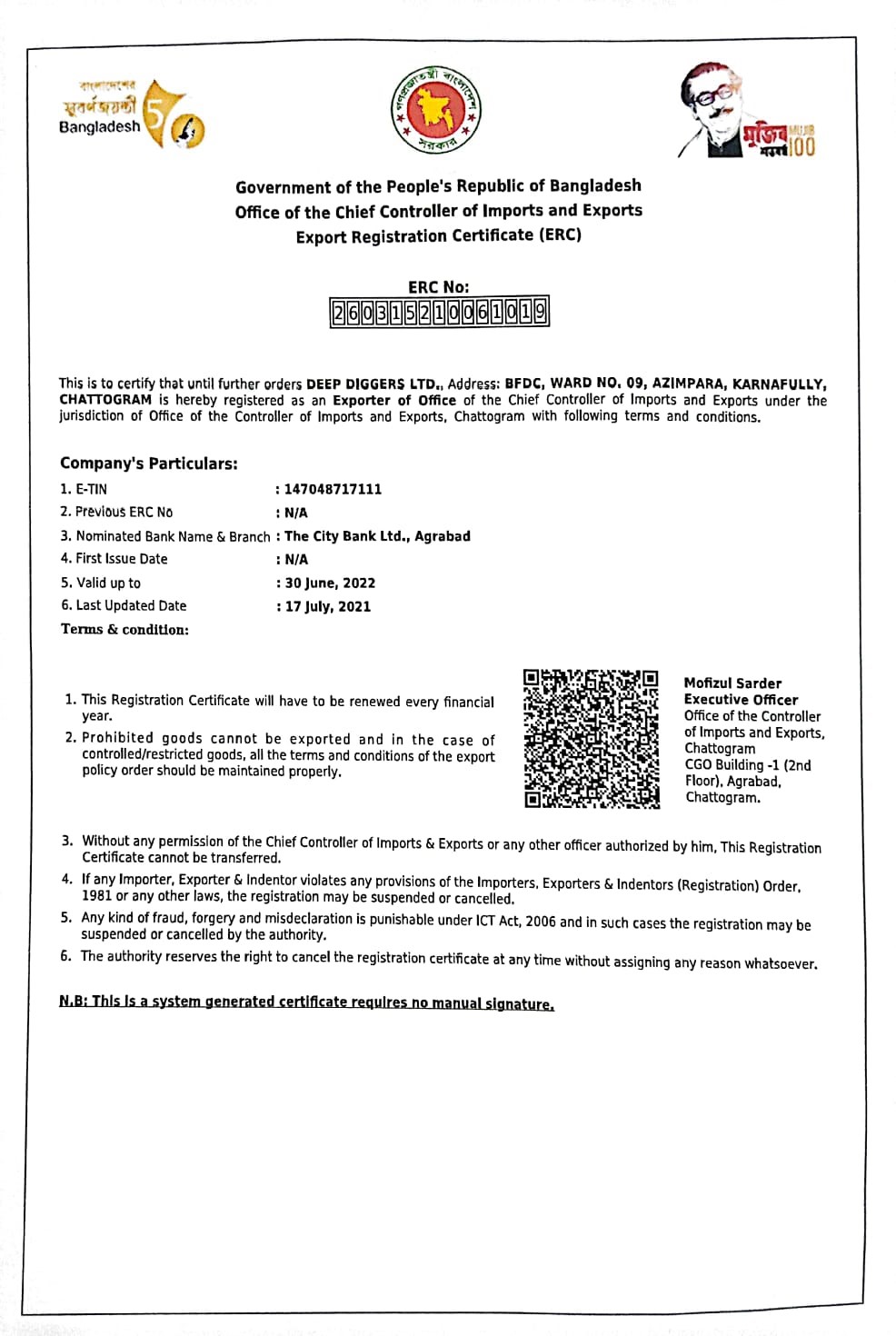

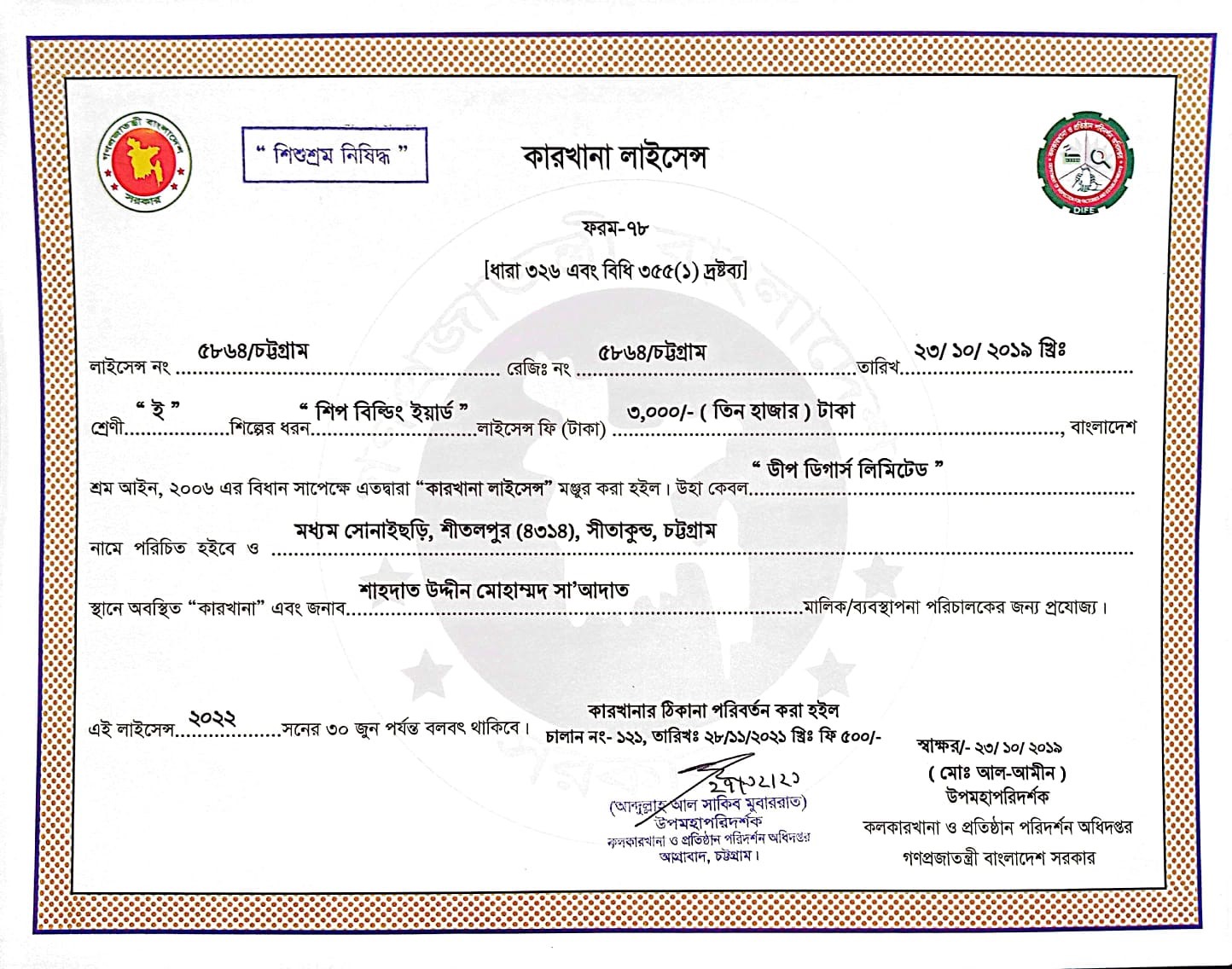

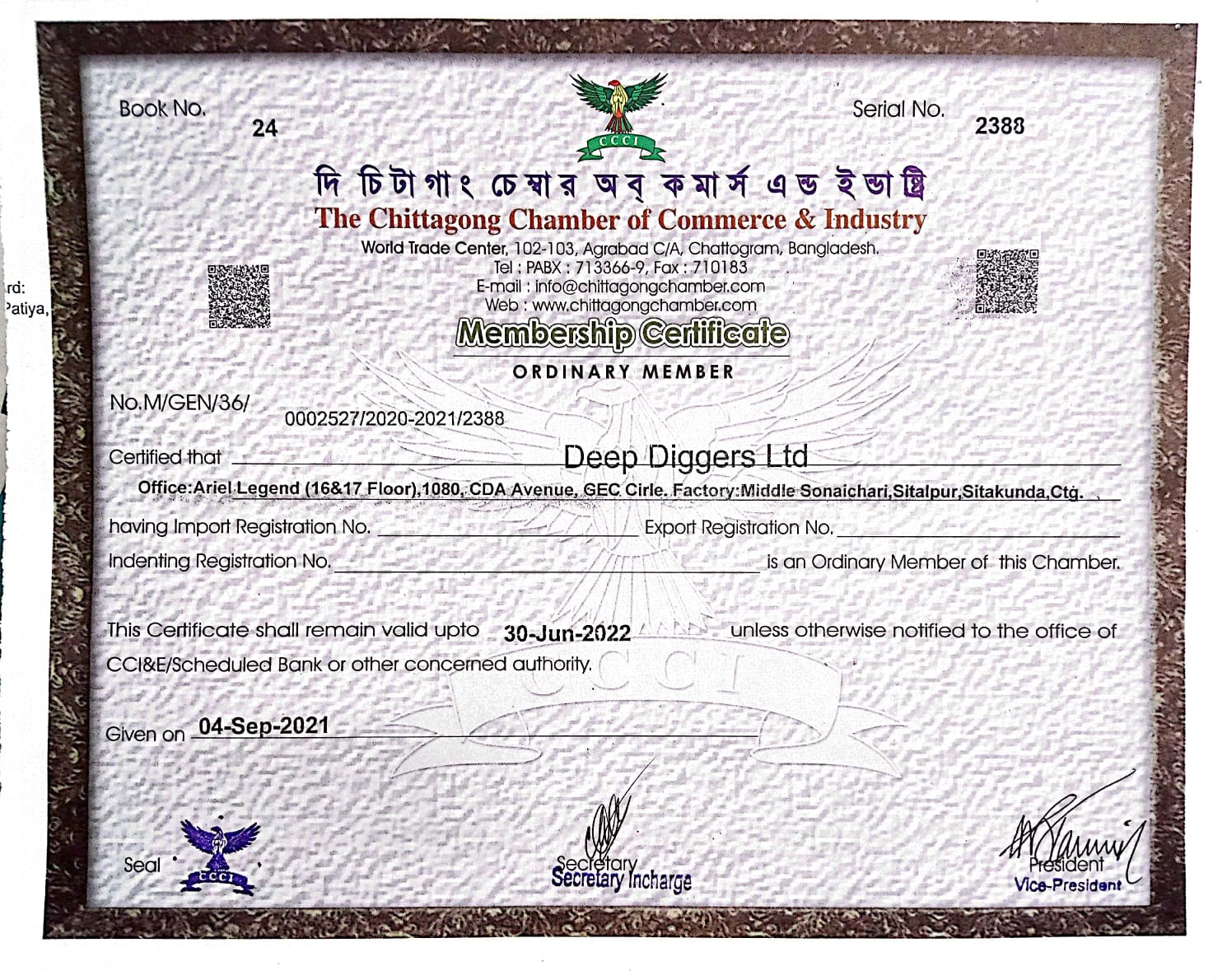

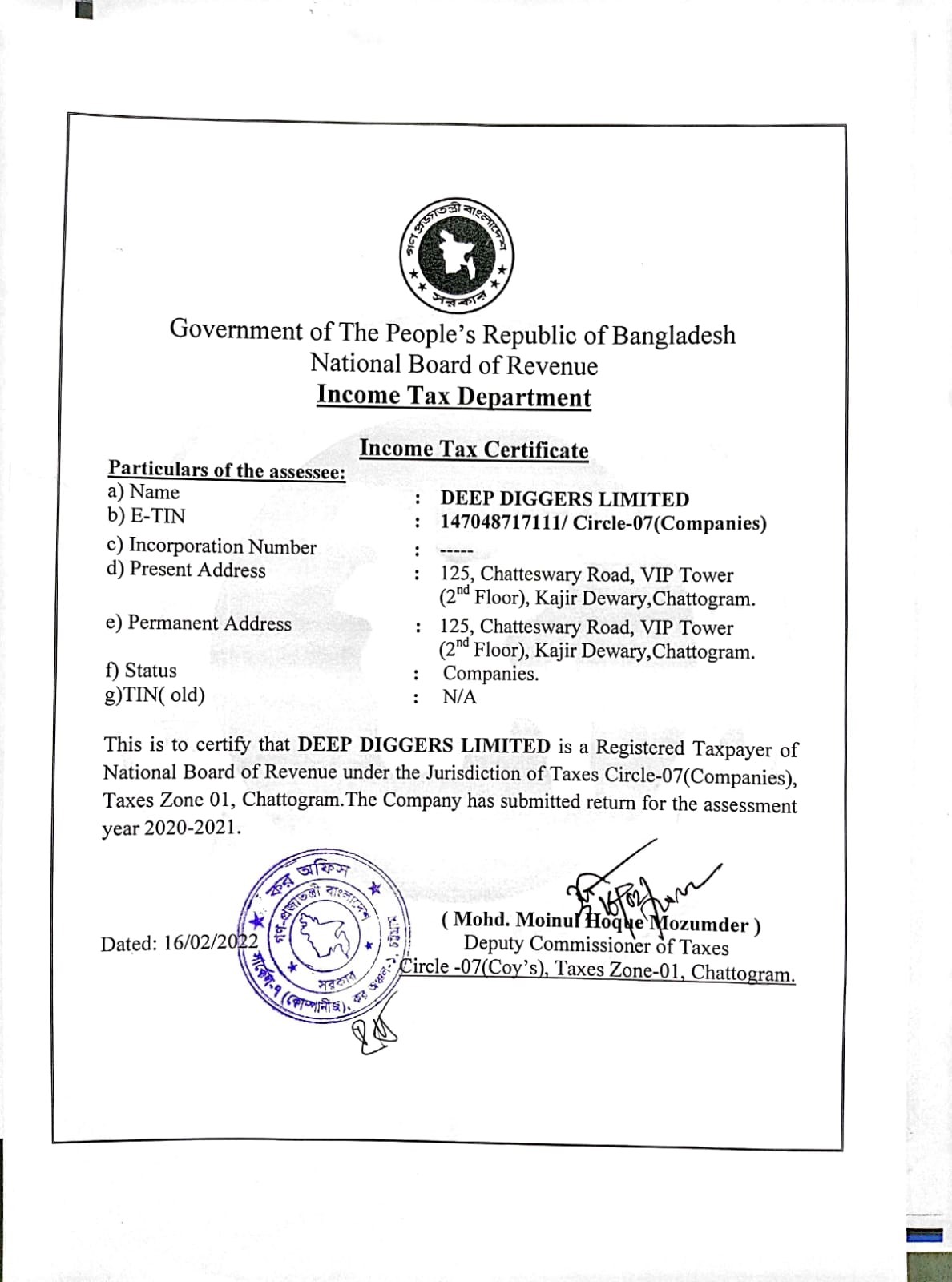

Licences and Certificates

Project Particulars at a Glance

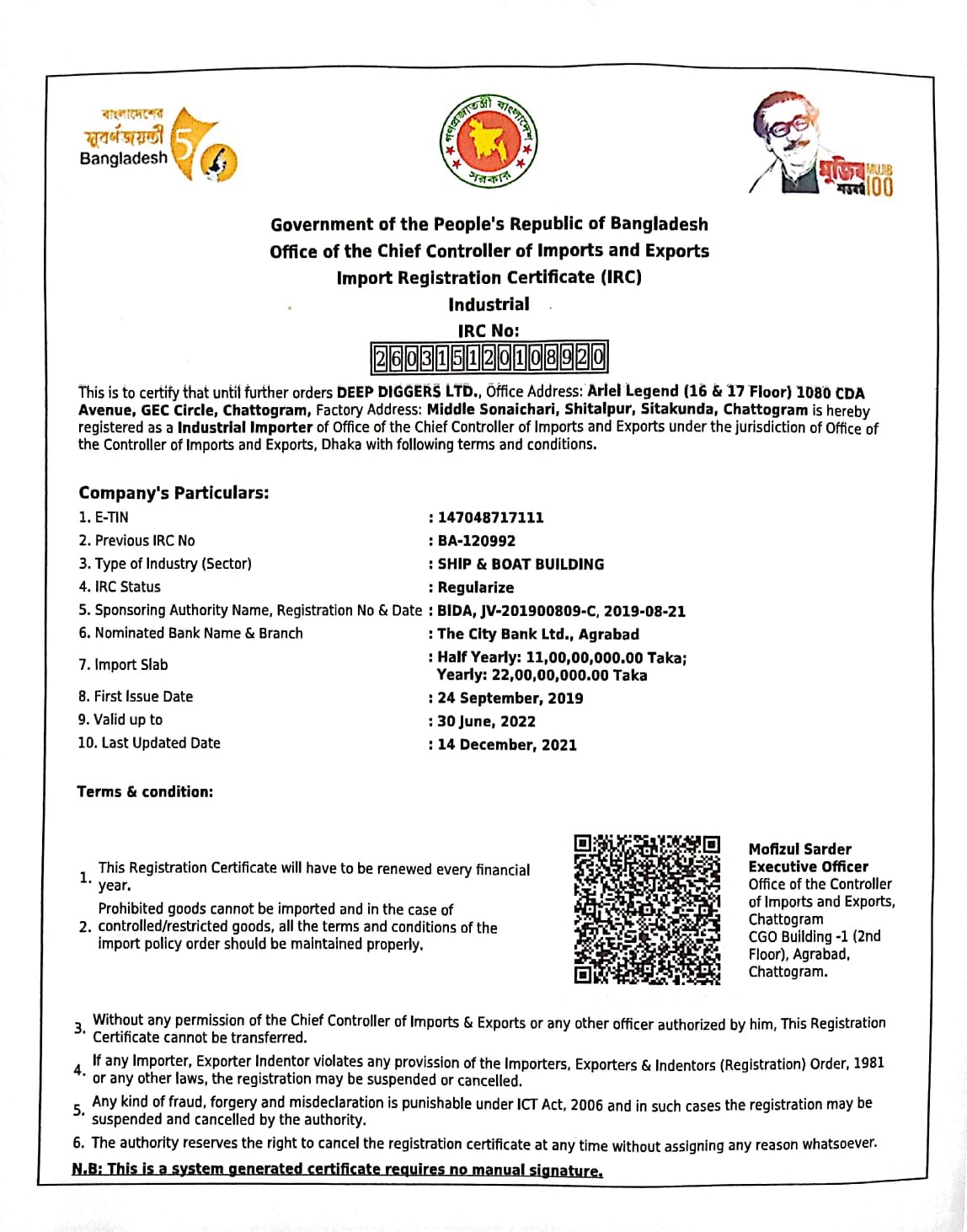

| Name of the Company | DEEP DIGGERS LIMITED |

|---|---|

| Office Address | 125, VIP Tower (2nd Floor), Kazir Dewri, Chattogram |

| Yard Location | 4 No. Kolagaon Union, Patiya, Chattogram |

| Nature of Business | Manufacturer of Dredgers, Work boat, House boat. |

| Legal Status | Limited Liability Company |

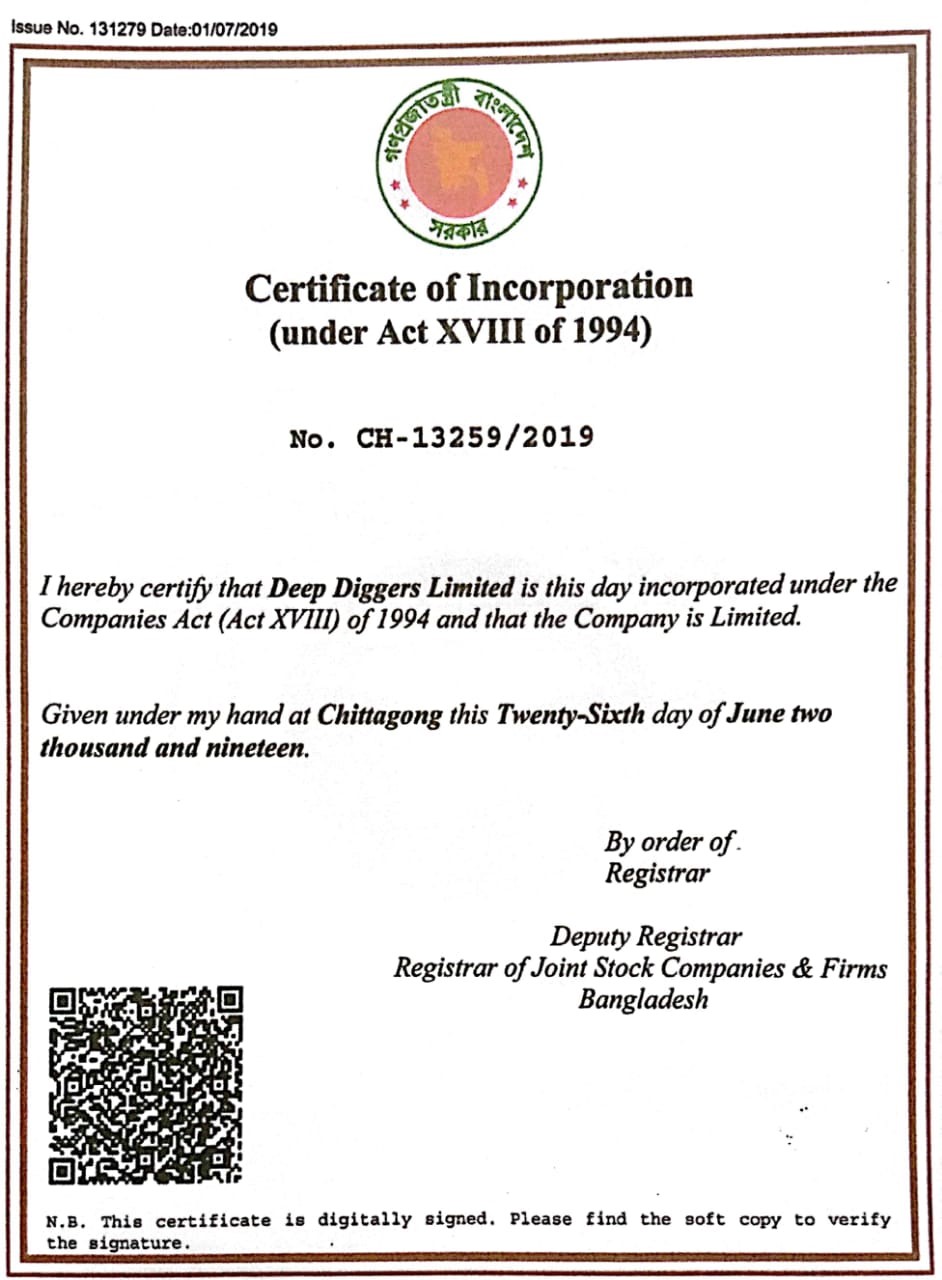

| Certificate of Incorporation | CH-13259/2019 |

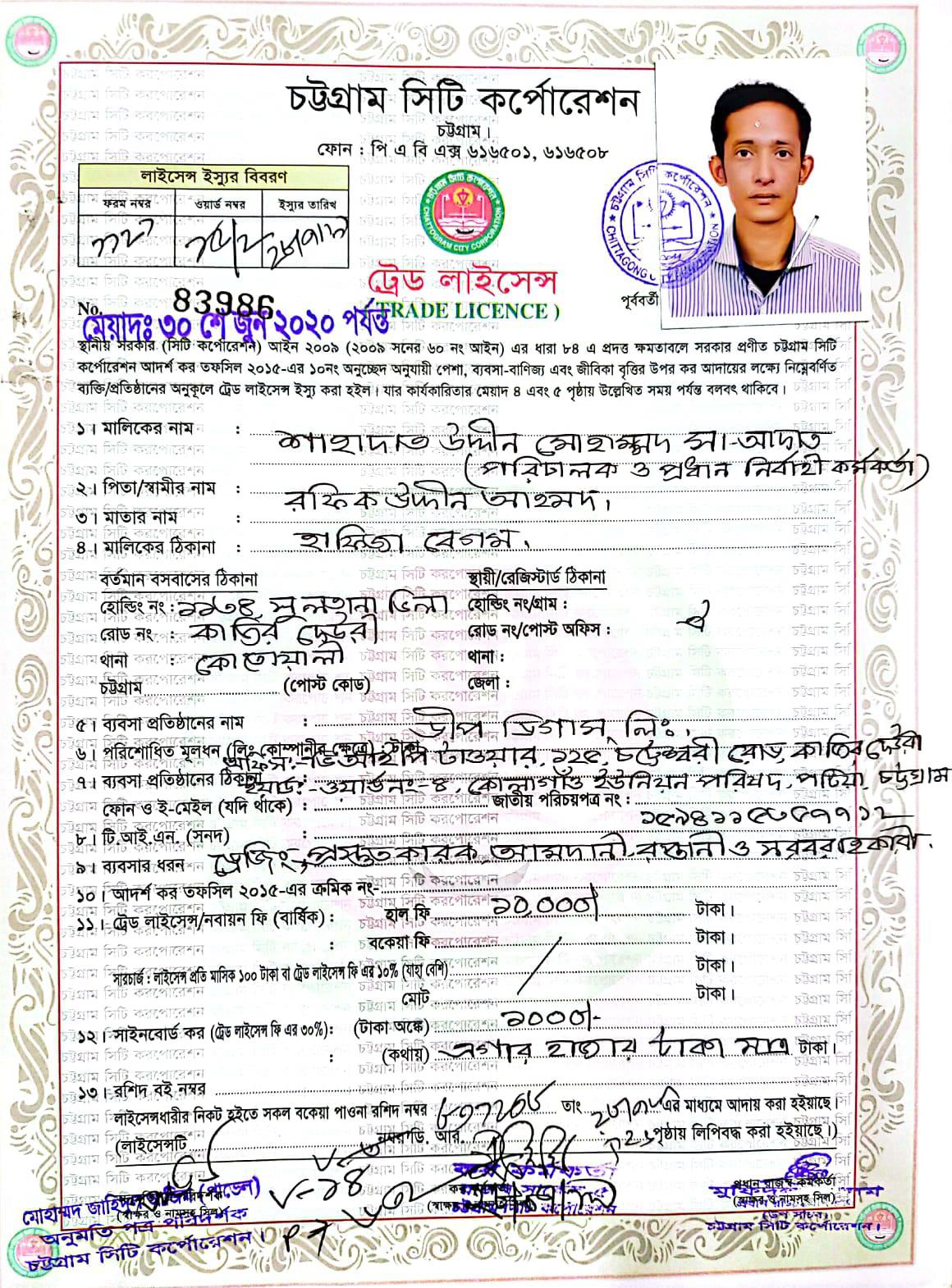

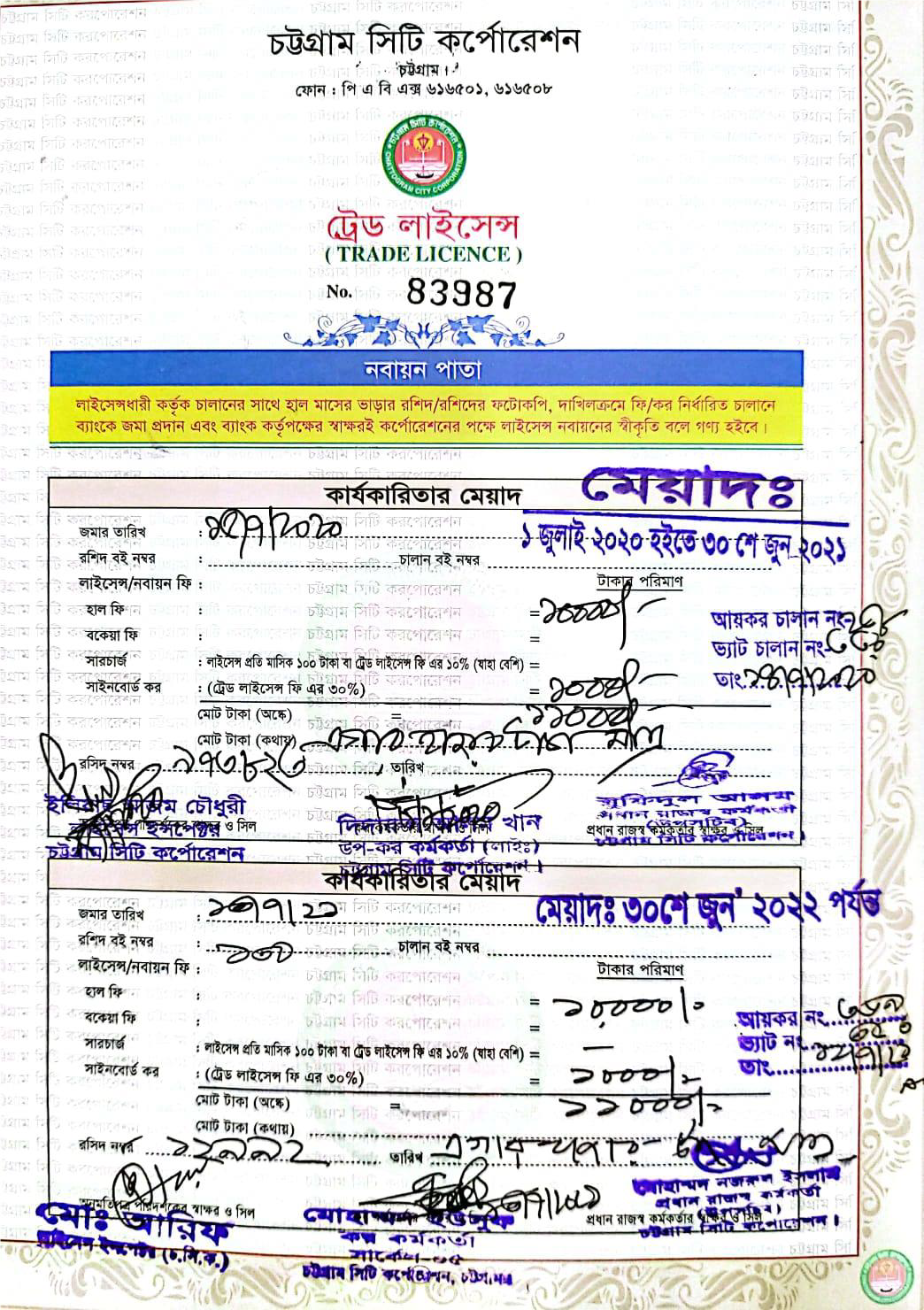

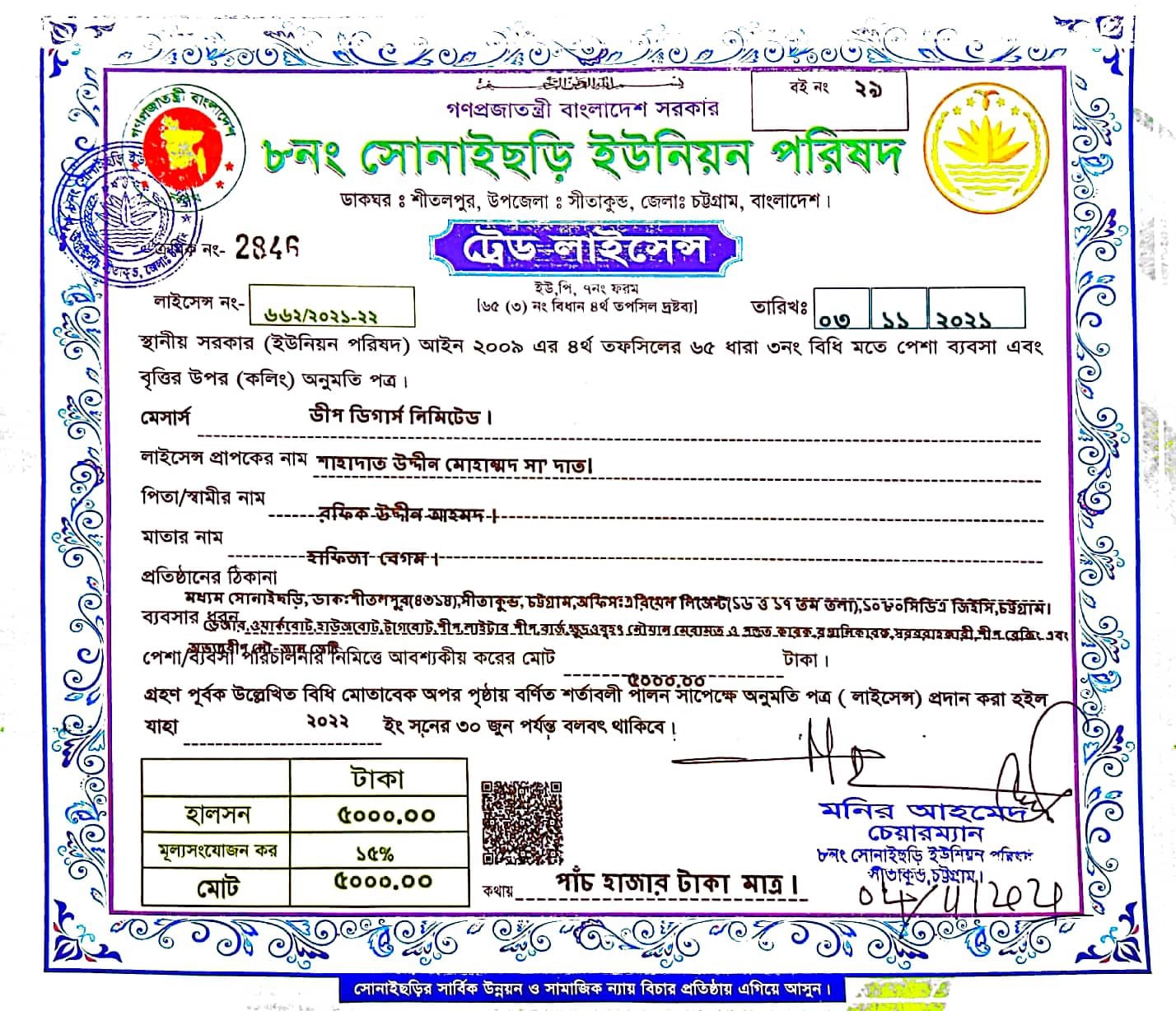

| Trade License Number | 83986 |

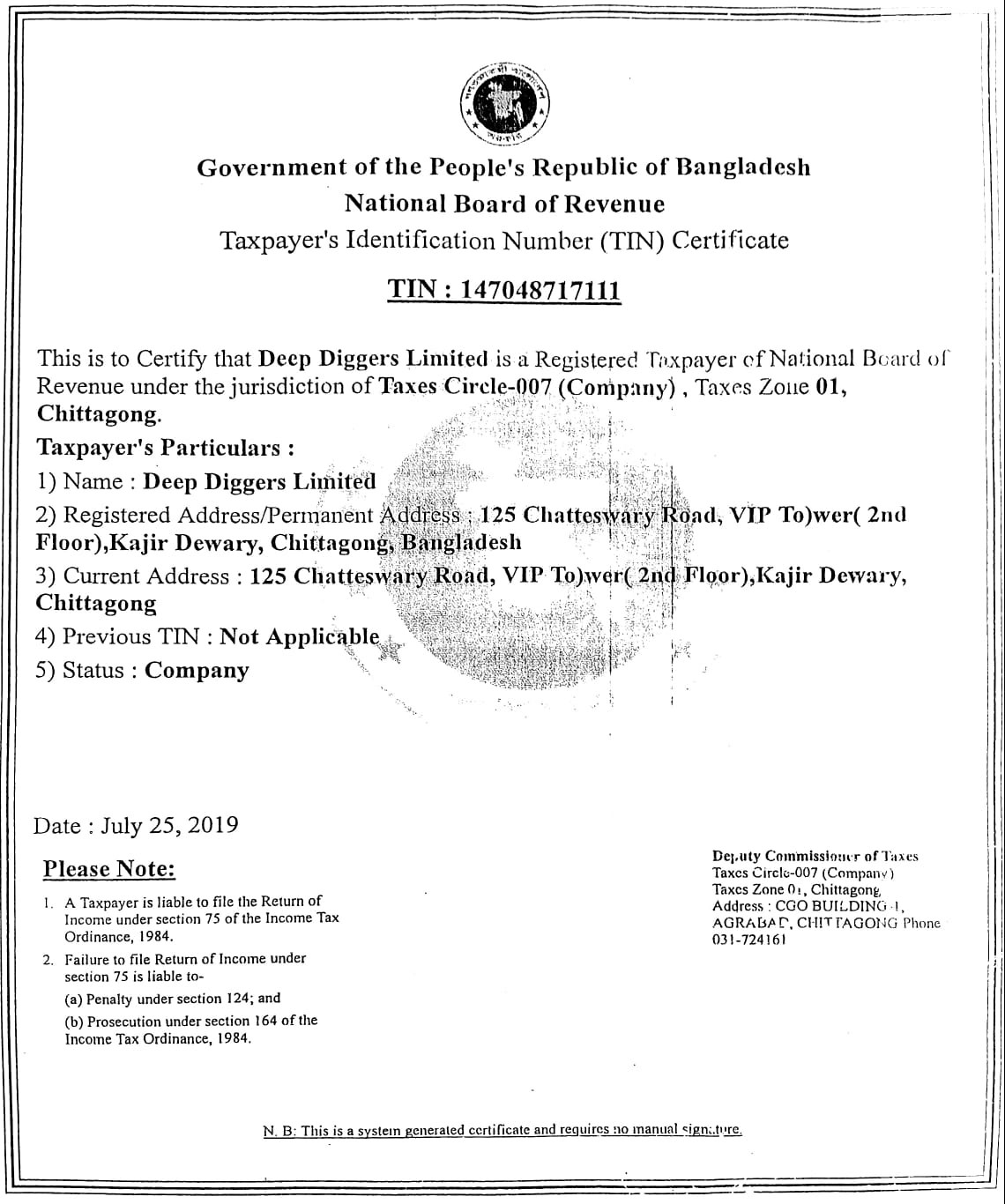

| TIN Number | 147048717111 (Circle – 007) |

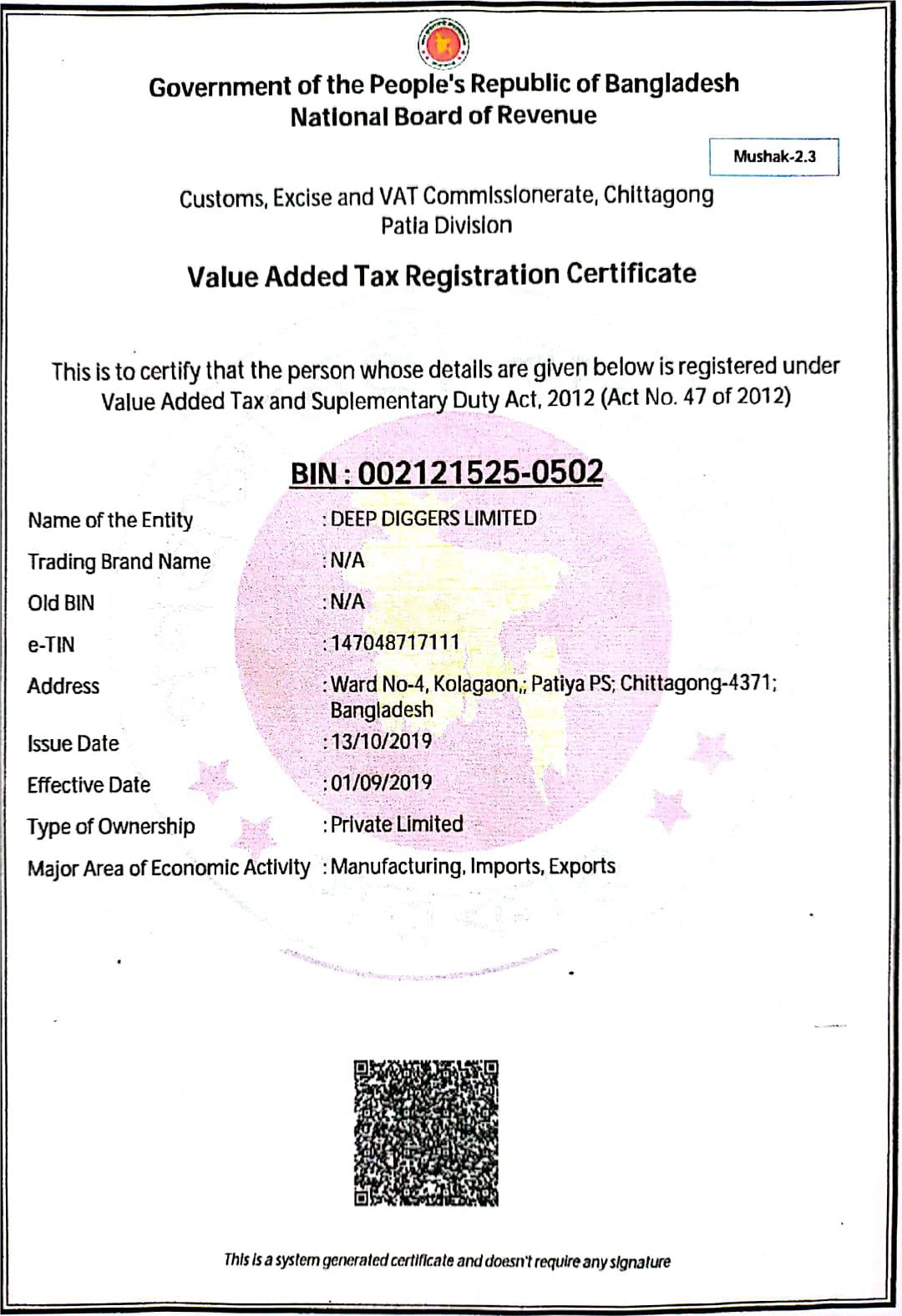

| VAT Registration Number | |

| Annual Manufacturing Capacity | 10 Dredgers (Standard) |

| Proposal of Term Loan | Taka 58.80 Crore |

| Proposal Working Capital | Taka 15.40 Crore (revolving) |

| Number of Employees | 100+ Persons (Officer & Workers) |

The Project is located at 4 No. Kolagaon Union, Patiya, Chattogram, Bangladesh. The location has physical infrastructure and utility facilities like road and rail communication, power, water, gas etc. are readily available.

The Directors of the Concern are

| Name | Designation |

|---|---|

| Gauhar Siraj Jamil | Chairman |

| Omar Sharif | Managing Director |

| Sahadat Uddin Mohammed Sadat | Director & CEO |

| Mohammed Rashedul Alam | Director & Technical Head |

| Zhang Changrong | Director |

| Mohammed Nur Nabi | Director |

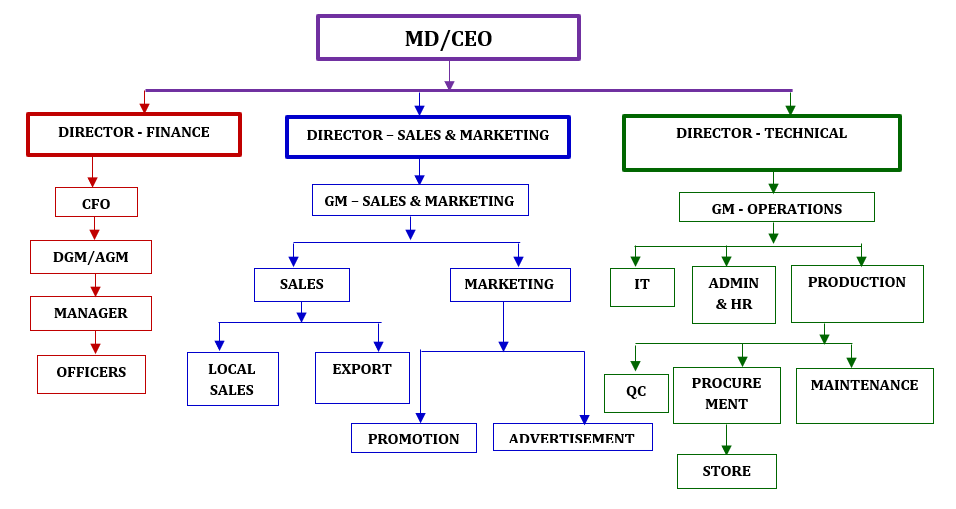

Organizational Structure

The project requires total 100+ human resources to operate. The business management of the company is divided in two different layers. One layer consists of the overall Total Management and the other layer consists of the organization Specific Management. However, all the decisions of the organization are taken combined by the organization’s Specific Management. We have taken adequate measures to ensure a healthy work environment in the manufacturing yard of dredgers and related products. Presently, the entire industry is required to comply with numbers of compliance issues regarding ensuring safety to ensure the efficient execution of the manufacturing capacity. Moreover, the dredger manufacturing yard management complies with health & safety management policies, other relevant regulations etc.

Swot Analysis

The acronym for SWOT stands for Strengths, Weaknesses, Opportunities, Threats

SWOT analysis involves the collection and portrayal of information about internal and external factors that have, or may have, an impact on the evolution of an organization or business. The SWOT analysis comprises of organization’s internal strengths and weaknesses and external opportunities and threats. It provides a list of an organization’s strengths and weaknesses as indicated by an analysis of its resources and capabilities, plus a list of the threats and opportunities identified by an analysis of its environment. Strategic logic requires that the future pattern of actions to be taken should match strengths with opportunities to ward off threats and seek to overcome weaknesses. SWOT analysis gives an organization like DEEP DIGGERS LIMITED an insight of what they can do in future and how they can compete with their existing competitors using strengths. This tool is very significant to identify the current position of DEEP DIGGERS LIMITED relative to others. It helps the company to build competitive advantages based on their strengths and opportunities and remove threats posed by others through competitive strategies. The details of SWOT analysis of DEEP DIGGERS LIMITED is noted below:

-

STRENGTHS :

- DEEP DIGGERS LIMITED has a set of skilled employees and workers who are already equipped with the necessary knowledge and experience. This gives the entity a chance to flourish the business remaining competitive. Moreover, the technical know-how of Managing Director and Director-Technical is crucial to this business as the product requires consultancy services to operate smoothly. The technical know-how is one of the barriers to entry into this industry.

- The location of the establishment of DEEP DIGGERS LIMITED is advantageous for proper manufacturing of dredgers, tug boat, house boat and other related installations. Due to the rental of the yard at minimal cost, the cost of manufacturing dredgers and other related constructions may be reduced compared to other competitors in order to remain competitive.

- With the existing agreements with DSC Dredge LLC (USA) and E-Touch Shipping Engineering Co. Limited gave DEEP DIGGERS LIMITED a huge advantage to lead the market with quality products and will assist to promote a bond of professionalism and commercialism. The suppliers are one of the core strengths of the company as they provide the required major mechanical parts, spares, designs, knowledge sharing and other auxiliary supports needed for the entity to ensure sales & related consultancy assistance and secure the profitability.

- DEEP DIGGERS LIMITED is totally committed to provide total services to their clients irrespective of the size of consignment. They will plan, coordinate, supervise, document and monitor the entire movement system of consignment. To serve the clients of DEEP DIGGERS LIMITED, the management is comprised of a group of 100+ trained, efficient, service-oriented and motivated personnel in its dredger manufacturing yard. The personnel and technical know-how support to carry out the operations at the yard will generate enough revenue to continue to operate profitably.

- DEEP DIGGERS LIMITED is equipped with state-of-the-art dredger manufacturing yard for building dredgers, tug boats, house boats, pipe boats etc. The operations of producing the desired number of dredgers and other related products will generate adequate revenue. The synergy of trained and skillful personnel & efficient operational management system will bring forth success to the company.

-

WEAKNESSES :

- DEEP DIGGERS LIMITED has a lack of concentration in versatile product manufacturing such as lighter vessels, barges for increasing manufacturing capacity & efficiency. Complex manufacturing and market demand comprehension could be a judging factor in ensuring the overall success of the project.

- DEEP DIGGERS LIMITED does not use enterprise resource planning (ERP) software in operation management to cover all the core functions of planning, production, sales and distribution of the dredgers, tug boats, house boats etc.

- DEEP DIGGERS LIMITED lacks the efficient usage of in-house design formulation team for designing the suppliers’ dredgers i.e. DSC Dredge LLC, E-Touch Shipping Engineering Co. Limited. With the increasing investments & efforts in R&D, the entity would be able to utilize the potentials of the designing department which will contribute to the overall success of the company.

-

OPPORTUNITIES :

- As the demand of dredgers in the country for dredging river banks and removing soil sediment are increasing day by day; DEEP DIGGERS LIMITED has the perfect opportunity to increase the manufacturing of dredgers and related accessories for the market to step ahead of its rivals.

- The flexibility of freedom of action comes from being privately owned. It is the independence which gives them the opportunity to provide a variety of offers customized to specific needs.

- DEEP DIGGERS LIMITED is able to offer their clients a competitive rate structure. Jointly with their project clients and network of agents, they intend to support the ongoing infrastructure development projects and there remains an opportunity to increase the business to more governmental infrastructure development projects.

- To enter into new markets and regions, to serve additional clients, to expand courses to meet broader range of customer needs and to diversify operations can be the ideal opportunity for DEEP DIGGERS LIMITED to flourish its business.

- DEEP DIGGERS LIMITED intends to export and sell locally its products. Due to the increase in demand in the overseas neighboring market, the entity intends to sell as deemed export.

-

THREATS :

- The rapid expansion of existing dredger manufacturers and importers pose potential threats to DEEP DIGGERS LIMITED.

- Aggressive competition from traditional rivals and many equal size players in the market with all new features of services can attract more clients.

- Economic downturn, instable political situation and less supportive Government tactics can hinder overall trading which in turn will affect DEEP DIGGERS LIMITED to continue its business activities.

- Changes in regulation in various countries regarding export-import of dredger manufacturing parts and equipment and international trade barriers often pose threat to smooth operation of manufacturing and sales of dredgers and related solutions.

Corporate Social Responsibilty (CSR)

In today’s frequent changing world we realize that the biggest challenge is to ensure that our customers are always ahead of their competition. Our foresight and past experiences have enabled us to give maximum importance to our quality control team. The team will check and verify the documentation of the dredge building procedures and report on the parameters to meet the building manual as provided by DSC Dredge LLC and E-Touch Shipping Engineering Co. Limited. This team is critical to our operation as the product quality will depend on the proper inspection and supervision to meet the standard being followed. Based on the report of the team, the finalization of the dredger building work will be determined. Any negligence in ensuring the quality of the dredgers up to the required standard will eventually tarnish the reputation of DEEP DIGGERS LIMITED.

The quality systems are designed to deliver reliability, consistency and customization. We have robust quality control systems at each stage of the supply chain, i.e. right from procurement of raw material, manufacturing, and up to delivery of finished engineering solution and product. We endeavor to continuously upgrade our capabilities and update process controls with product checks to ensure complete customer satisfaction. The company recognizes that its employees are the primary source of success in its operations and is committed to their training, providing them with the necessary tools and techniques, as well as fostering a culture of quality in the organization at all levels. The Quality Control (QC) team will check the quality of the dredgers and related accessories before the delivery ensuring the reputation of the brand and its products.

Quality Control

DEEP DIGGERS LIMITED has put huge emphasis on its corporate social responsibilities. The social welfare activity of the entity is mainly concentrated in establishing Orphanage, Madrasa for Orphans, and Voluntary Service to the dead people through Anjuman Mufidul Islam, health, safety, donations in school and college

DEEP DIGGERS LIMITED always disburses large contributions through social welfare. We have a bifocal objective of making profits through the fulfillment of corporate social responsibilities. We sincerely believe in developing the community in which it operates a corporate mission embodies in itself corporate social responsibilities with the additional compulsion to make profits in order to thrive and grow which must be fulfilled in greater measure as time passes. We also encourage our corporate clients to extend their generosity to ensure the well-being of under-privileged women and children.

The dredger manufacturing industry does not compromise on environmental responsibility. Steel is the world’s most recycled material and 100% recyclable. We have implemented good waste management technology to the point where only the limits of science confine our ability to improve. As the world looks for solutions to its environmental challenges, all of these depend on steel.

Execution Team

We will form a team of sourcing experts who under the guidance of our directors, source exact & quality products from our reliable sources. Under them, we have a team of quality controllers who check the quality of the spares before they are assembled, stored or distributed. Our experienced Operations team, who ensure that all the needs of the customers are communicated in a proper, timely manner to our various personnel in the sourcing, handling and the team. They also ensure regular communication with our customers, and are available round the clock, if our customer needs any information or assistance.